Table of Contents

The coolant temperature sensor (CTS), sometimes called the coolant temperature switch, is one of the most important components in an engine management system. Its primary purpose is to monitor the coolant temperature and send data to the vehicle’s computer. This allows the ECU to adjust fuel delivery, ignition timing, and other engine parameters for smooth performance.

When this sensor malfunctions, it can lead to inaccurate readings, poor fuel economy, rough idling, and even overheating. Just like transmission slipping creates driving issues if left unchecked just like transmission slipping can cause serious issues if you skip regular transmission fluid maintenance, a failing coolant temperature sensor can cause significant mechanical problems and reduce your vehicle’s efficiency. In this blog we will dive into the most common symptoms of a bad coolant temperature sensor.

Symptoms Of A Bad Coolant Temperature Sensor

Overheating Engine

If your engine is overheating often, the coolant temperature sensor may be the culprit. A defective sensor can send inaccurate “hot” signals to the ECU, causing the system to make incorrect adjustments. This can create overheating, similar to how transmission slipping worsens when the transmission fluid levels are off. Ignoring overheating can result in severe engine damage; regular engine maintenance can help prevent this..

Poor Fuel Economy

A faulty CTS can confuse the computer into thinking the engine is always cold. As a result, it unnecessarily enriches the fuel mixture, causing your car to burn more fuel — another reason to follow a consistent car maintenance checklist. Over time, this leads to poor fuel efficiency much like transmission slipping reduces fuel economy because the engine has to work harder to maintain speed.

Check Engine Light

An illuminated Check Engine light is a clear warning that something is wrong. If the computer detects erratic signals from the coolant temperature sensor, it will trigger this alert. Just as transmission slipping often brings up diagnostic trouble codes, a malfunctioning CTS typically stores error codes that can be identified with an OBD2 scanner.

Black Smoke from Exhaust

Excessively rich fuel mixtures caused by a bad sensor can lead to incomplete combustion. This often shows up as thick black smoke from the tailpipe, a sign many drivers overlook. This situation not only harms your vehicle’s performance but can also fail emissions tests. Just like ignoring transmission slipping can result in costly transmission damage, neglecting this symptom could shorten your engine’s life.

Rough or Poor Idling

When the air-fuel mixture isn’t correct, engines tend to idle roughly, vibrate at low speeds, or even stall. Many drivers report power loss or inconsistent performance due to a bad CTS. This jerky behavior is comparable to how transmission slipping makes shifting feel rough and unpredictable.

Cooling Fan Malfunctions

In some vehicles, the coolant temperature sensor helps control the operation of cooling fans. If the sensor fails, it may prevent the fans from turning on at the right time, increasing the risk of overheating. Since overheating also worsens transmission slipping problems, this makes a bad coolant sensor a double danger to both your engine and transmission health.

Primary Functions of the Coolant Temperature Sensor

The coolant temperature sensor serves multiple essential purposes in modern vehicles:

- Fuel Mixture Control: The ECU adjusts the air-fuel ratio based on engine temperature, running a richer mixture when cold and leaner when warm

- Ignition Timing Optimization: The sensor data helps determine the ideal spark timing for efficient combustion at various temperatures

- Transmission Shift Points: Automatic transmissions use temperature data to adjust shift timing and torque converter lockup

- Radiator Fan Activation: The sensor signals when the cooling fans should engage to prevent overheating

- Dashboard Temperature Gauge: Provides the driver with real-time temperature information through the instrument cluster

- Emission Control: Helps regulate emission control systems to maintain compliance with environmental standards

Types of Coolant Temperature Sensors

Understanding the different types of coolant temperature sensors can help you identify which system your vehicle uses:

| Sensor Type | Technology | Common Applications | Voltage Range |

|---|---|---|---|

| Negative Temperature Coefficient (NTC) | Resistance decreases as temperature increases | Most modern vehicles, standard applications | 0-5 volts |

| Positive Temperature Coefficient (PTC) | Resistance increases as temperature increases | Older vehicles, specialized applications | Variable |

| Dual Sensor Systems | Separate sensors for ECU and gauge | Performance vehicles, heavy-duty applications | System dependent |

| Infrared Sensors | Non-contact temperature measurement | Advanced hybrid/electric vehicles | Digital signal |

The NTC thermistor remains the most common type found in contemporary vehicles due to its accuracy, reliability, and cost-effectiveness.

Symptoms of a Bad Coolant Temperature Sensor

| Symptom | Description | Possible Consequence |

| Overheating Engine | Sends false “hot” signals to ECU, leading to incorrect adjustments. | Severe engine damage if ignored |

| Poor Fuel Economy | ECU enriches the mixture, thinking the engine is cold. | Increased fuel consumption and higher costs |

| Check Engine Light | ECU detects erratic signals, triggering diagnostic trouble codes. | Requires OBD2 scan to confirm issue |

| Black Smoke from Exhaust | Rich fuel mixtures cause incomplete combustion and visible black smoke. | Failed emissions test and reduced engine life |

| Rough or Poor Idling | Incorrect air-fuel mixture leads to vibration, stalling, or power loss. | Unreliable driving performance |

| Cooling Fan Malfunctions | Sensor failure prevents fans from switching on at correct times. | Higher risk of overheating and related damage |

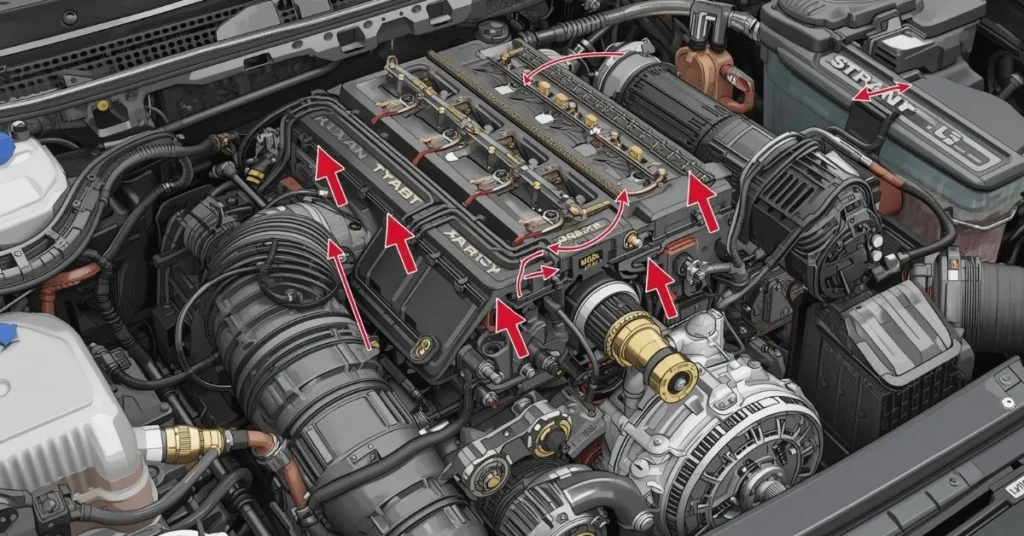

Where Is The Coolant Temperature Sensor Located?

The location of the coolant temperature sensor can vary depending on the car’s make, model, and overall design. Generally, it is mounted on the cylinder head or engine block, often positioned along a plastic hose at the coolant inlet. In some vehicles, there may be more than one coolant temperature sensor, each serving different functions such as sending signals to the engine control unit (ECU), dashboard gauge, or cooling fan. Typically, when two sensors are present, the one that communicates with the ECU is specifically referred to as the coolant temperature sensor.

Diagnosing Coolant Temperature Sensor Problems

Proper diagnosis ensures you replace the correct component and avoid unnecessary repairs:

Visual Inspection

Begin by examining the sensor and its wiring harness for obvious damage, corrosion, or loose connections. Check for coolant leaks around the sensor mounting area, as coolant contamination can damage the electrical connector.

Resistance Testing

Using a digital multimeter, measure the sensor’s resistance at various temperatures and compare the readings to manufacturer specifications. A properly functioning sensor shows predictable resistance changes corresponding to temperature variations.

Scanner Diagnosis

An OBD-II scanner provides the most comprehensive diagnostic information, displaying real-time temperature readings and stored trouble codes. Compare the sensor reading with the actual engine temperature to identify discrepancies.

Coolant Temperature Sensor Replacement Guide

Replacing a faulty coolant temperature sensor is a straightforward process that most DIY mechanics can accomplish:

Tools and Materials Needed

- New coolant temperature sensor (OEM or quality aftermarket)

- Socket wrench set

- Thread sealant or Teflon tape

- Drain pan

- Fresh coolant

- Shop towels

Step-by-Step Replacement Process

- Prepare the Vehicle: Allow the engine to cool completely and disconnect the negative battery cable

- Locate the Sensor: Identify the sensor position, typically found near the thermostat housing or on the engine block

- Drain Coolant: Partially drain the cooling system to prevent coolant loss during removal

- Disconnect Electrical Connector: Carefully unplug the wiring harness from the sensor

- Remove Old Sensor: Use the appropriate socket to unscrew the sensor from its mounting location

- Install New Sensor: Apply thread sealant if required, and install the new sensor to manufacturer torque specifications

- Reconnect and Refill: Attach the electrical connector, refill the cooling system, and bleed air from the system

- Test Operation: Start the engine, check for leaks, and verify proper temperature readings

Maintenance Tips to Extend Sensor Life

Proactive maintenance can significantly extend the lifespan of your coolant temperature sensor:

- Regular Coolant Changes: Follow manufacturer-recommended intervals to prevent corrosion and contamination

- Use Quality Coolant: Always use the specified coolant type to prevent chemical damage to sensor components

- Inspect Electrical Connections: Periodically check connectors for corrosion and ensure tight, secure connections

- Monitor Temperature Gauge: Pay attention to your temperature gauge during normal driving to catch problems early

- Address Cooling System Issues Promptly: Fix leaks, replace worn hoses, and maintain proper system pressure

Cost Considerations

The cost of coolant temperature sensor replacement varies based on vehicle make, model, and location:

| Cost Component | Price Range |

|---|---|

| Sensor Part (Economy) | $15 – $35 |

| Sensor Part (OEM) | $40 – $120 |

| Labor (Professional) | $75 – $150 |

| Total DIY Cost | $15 – $120 |

| Total Professional Cost | $90 – $270 |

While DIY replacement offers significant savings, professional installation ensures proper diagnosis and correct installation, which may be worthwhile for complex vehicle systems.

For more in-depth insights on engine reliability, common engine problems, and replacement decisions, explore our complete collection of engine guides.

Conclusion

The coolant temperature sensor represents a small investment with enormous implications for engine performance, efficiency, and longevity. This critical component ensures your engine management system receives accurate temperature data, enabling optimal operation across all driving conditions. By understanding how this sensor functions, recognizing failure symptoms early, and performing timely replacements, you can avoid costly repairs and keep your vehicle running at peak performance.

Don’t ignore the warning signs of a failing coolant temperature sensor. Whether you choose to tackle the replacement yourself or entrust the job to a professional mechanic, addressing sensor issues promptly protects your engine and ensures reliable transportation for years to come. Regular maintenance and attention to your vehicle’s cooling system will reward you with dependable performance and peace of mind on every journey.

Frequently Asked Questions

-

How long does a coolant temperature sensor last?

Most coolant temperature sensors last between 100,000 to 150,000 miles under normal operating conditions. However, factors like coolant quality, heat exposure, and electrical issues can affect longevity.

-

Can I drive with a bad coolant temperature sensor?

While you can drive short distances with a faulty sensor, it’s not recommended. The incorrect data can cause poor fuel economy, increased emissions, potential engine damage from improper fuel mixture, and possible overheating without warning.

-

Will a bad coolant sensor throw a code?

Yes, a malfunctioning sensor typically triggers the check engine light and stores diagnostic trouble codes. However, intermittent failures may not always generate codes immediately.

-

Is the coolant sensor the same as the thermostat?

No, these are different components. The thermostat regulates coolant flow to maintain proper engine temperature, while the sensor monitors and reports temperature data to the ECU.

-

Can a coolant sensor cause overheating?

Indirectly, yes. If the sensor fails and sends incorrect data, it may prevent cooling fans from activating when needed, leading to actual overheating conditions.