Table of Contents

When engineers design roads and highways, they face a critical challenge: how to create pavement structures that can withstand decades of traffic without premature failure. The answer lies in a crucial engineering metric known as Million Standard Axles (MSA). This fundamental concept in pavement design determines the structural capacity required for roads to endure the cumulative impact of vehicle traffic over their intended lifespan.

Understanding MSA is essential for civil engineers, highway planners, contractors, and anyone involved in road construction and maintenance. This comprehensive guide explores the concept of Million Standard Axles, its calculation methods, applications in pavement design, and its critical role in creating durable, cost-effective road infrastructure that serves communities for generations.

Reliability trends play a quiet but powerful role in traffic design. Insights from Toyota vs Honda Reliability help illustrate how dependable vehicles influence real-world pavement wear patterns.

What Are Million Standard Axles (MSA)?

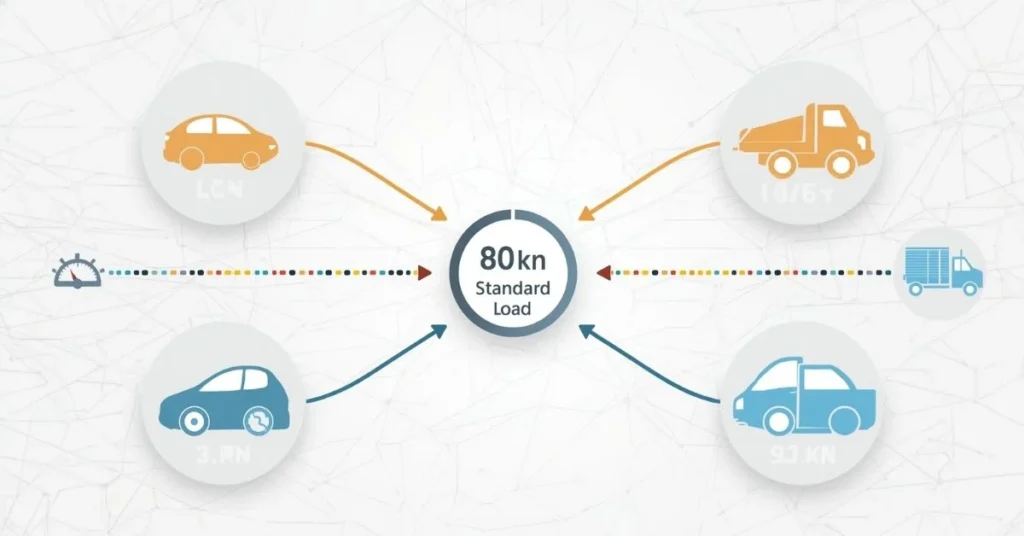

Million Standard Axles (MSA), also known as Equivalent Standard Axle Load (ESAL) in millions, is a unit of measurement used in pavement design to quantify the cumulative damage caused by mixed traffic over a road’s design life. The concept converts the varying axle loads of different vehicles into equivalent standard axle loads, allowing engineers to design pavements with appropriate structural strength.

The standard axle load is typically defined as a single axle with dual wheels carrying 80 kN (18,000 pounds or 8.16 metric tons). This standard was established based on extensive research and represents a common heavy vehicle configuration. All other vehicle loads are converted to their equivalent impact relative to this standard.

The Foundation of Modern Pavement Design

The MSA concept emerged from the landmark AASHO Road Test conducted in the late 1950s and early 1960s in Illinois, USA. This extensive research project established the relationship between axle loads and pavement damage, revealing that pavement deterioration increases exponentially with axle weight rather than linearly.

The concept of Million Standard Axles was born from the historic AASHO Road Test, a landmark study that shaped pavement design standards worldwide.

Why Million Standard Axles Matter in Road Construction

The importance of MSA in pavement engineering cannot be overstated:

- Structural Adequacy: Ensures pavements have sufficient thickness and strength to handle expected traffic loads

- Economic Efficiency: Prevents over-design (wasting resources) or under-design (premature failure)

- Lifespan Prediction: Helps estimate when pavements will require rehabilitation or reconstruction

- Maintenance Planning: Enables highway agencies to budget and schedule maintenance activities

- Performance Standards: Provides a standardized metric for comparing different pavement designs

- Regulatory Compliance: Meets engineering standards and specifications for road construction projects

Understanding the Fourth Power Law

The relationship between axle load and pavement damage follows the fourth power law, a critical principle in pavement engineering. This law states that pavement damage increases approximately with the fourth power of the axle load ratio.

Mathematical Representation

Damage Factor = (Actual Axle Load / Standard Axle Load)⁴

This exponential relationship has profound implications:

| Axle Load Increase | Relative Damage Factor |

| Standard Load (80 kN) | 1.0x |

| 1.5x Standard (120 kN) | 5.06x |

| 2x Standard (160 kN) | 16.0x |

| 2.5x Standard (200 kN) | 39.1x |

| 3x Standard (240 kN) | 81.0x |

This table dramatically illustrates why overloaded vehicles cause disproportionate damage. A vehicle with twice the standard axle load causes approximately 16 times more pavement damage than a standard axle load.

Calculating Million Standard Axles

The calculation of Million Standard Axles involves several steps and requires detailed traffic data:

Step 1: Traffic Survey and Classification

Engineers conduct comprehensive traffic surveys to determine:

- Daily traffic volume by vehicle class

- Axle configuration for each vehicle type (single, tandem, tridem)

- Actual axle loads through weigh-in-motion (WIM) stations or load surveys

- Traffic distribution by direction and lane

- Projected traffic growth rates over the design period

Step 2: Load Equivalency Factors

Each vehicle type and axle configuration has a Load Equivalency Factor (LEF) that converts its damage to standard axle equivalents. Common equivalency factors include:

| Vehicle Type | Typical Axle Configuration | Approximate LEF Range |

| Passenger Car | Single axle, single wheel | 0.0001 – 0.0005 |

| Light Commercial Vehicle | Single axle, dual wheel | 0.01 – 0.1 |

| Two-Axle Truck | Single + single axle | 0.5 – 2.0 |

| Three-Axle Truck | Single + tandem axle | 1.0 – 3.0 |

| Multi-Axle Truck | Various configurations | 2.0 – 5.0+ |

| Fully Loaded Trailer | Multiple axle combinations | 3.0 – 8.0+ |

Step 3: MSA Calculation Formula

MSA = (ADT × P × LEF × 365 × N × DF × LF) / 1,000,000

Where:

- ADT = Average Daily Traffic (vehicles per day)

- P = Percentage of commercial vehicles

- LEF = Load Equivalency Factor

- 365 = Days per year

- N = Design life in years

- DF = Direction Distribution Factor (typically 0.5 for two-way roads)

- LF = Lane Distribution Factor (varies by number of lanes)

Practical Calculation Example

Consider a two-lane highway with the following characteristics:

- Average Daily Traffic: 5,000 vehicles

- Commercial vehicles: 20%

- Average LEF for commercial vehicles: 2.5

- Design life: 20 years

- Direction factor: 0.5

- Lane factor: 1.0 (single lane per direction)

MSA = (5,000 × 0.20 × 2.5 × 365 × 20 × 0.5 × 1.0) / 1,000,000 MSA = 18.25 Million Standard Axles

MSA Categories and Pavement Design Implications

Highway agencies typically classify roads based on their MSA values to determine appropriate pavement designs:

| MSA Category | Traffic Classification | Typical Application | Pavement Thickness Range |

| < 0.5 MSA | Very Light Traffic | Rural access roads, residential streets | 150-250 mm |

| 0.5 – 2 MSA | Light Traffic | Local roads, minor collectors | 250-350 mm |

| 2 – 10 MSA | Medium Traffic | Major collectors, secondary highways | 350-500 mm |

| 10 – 30 MSA | Heavy Traffic | Primary highways, state routes | 500-700 mm |

| > 30 MSA | Very Heavy Traffic | Interstate highways, major urban routes | 700-1000+ mm |

These thickness ranges represent total pavement structure including surface, base, and sub-base layers, and vary based on subgrade soil conditions and climate.

Factors Influencing MSA Requirements

Several critical factors affect MSA calculations and pavement design:

Traffic-Related Factors

- Vehicle Weight Regulations: Enforcement of axle load limits significantly impacts actual MSA

- Traffic Growth: Economic development increases commercial vehicle volumes

- Freight Patterns: Industrial corridors experience higher MSA than tourist routes

- Seasonal Variations: Agricultural regions see traffic spikes during harvest seasons

Environmental Considerations

- Climate Conditions: Freeze-thaw cycles, high temperatures, and moisture affect pavement performance

- Subgrade Strength: Soil bearing capacity influences required pavement thickness

- Drainage Quality: Proper drainage extends pavement life and affects MSA capacity

- Temperature Extremes: Both hot and cold climates present unique challenges

Design and Material Factors

- Pavement Type: Flexible (asphalt) versus rigid (concrete) pavements respond differently to loads

- Material Quality: Higher-grade materials provide better load distribution

- Construction Standards: Proper compaction and quality control affect actual performance

- Maintenance History: Well-maintained pavements better resist cumulative damage

MSA in Flexible Versus Rigid Pavement Design

The application of Million Standard Axles differs between flexible and rigid pavement systems:

Flexible Pavement (Asphalt)

Flexible pavements distribute loads through multiple layers:

- Surface course absorbs and distributes wheel loads

- Base course provides structural strength and load spreading

- Sub-base provides additional support and drainage

- Each layer must withstand the calculated MSA over the design life

Design methods like the Asphalt Institute method or mechanistic-empirical approaches use MSA as a primary input parameter.

Rigid Pavement (Concrete)

Rigid pavements rely on slab action and beam strength:

- Concrete slab provides primary structural capacity

- Load transfer at joints through dowels or aggregate interlock

- Base/sub-base provides uniform support and prevents pumping

- Design focuses on slab thickness, joint spacing, and reinforcement

The Portland Cement Association (PCA) method and other rigid pavement design procedures incorporate MSA to determine required slab thickness.

Modern Approaches to MSA: Mechanistic-Empirical Design

Contemporary pavement design has evolved beyond simple MSA calculations toward mechanistic-empirical methods:

The Mechanistic-Empirical Pavement Design Guide (MEPDG)

This advanced approach, now implemented as AASHTOWare Pavement ME Design:

- Analyzes actual traffic spectra rather than simplified MSA

- Considers monthly variations in traffic and climate

- Predicts specific distress types (rutting, cracking, faulting)

- Provides probabilistic reliability estimates

- Still uses equivalent single axle loads but with greater sophistication

While MEPDG represents the cutting edge, traditional Million Standard Axles remain widely used for preliminary design, project classification, and smaller projects where detailed traffic data is unavailable.

Common Challenges in MSA Estimation

Accurately determining MSA presents several practical challenges:

Data Collection Limitations

- Incomplete Traffic Data: Many roads lack comprehensive vehicle classification data

- Weigh-in-Motion Accuracy: WIM systems require calibration and maintenance

- Seasonal Sampling: Short-term counts may not represent annual patterns

- Illegal Overloading: Unregulated overweight vehicles cause unpredicted damage

Prediction Uncertainties

- Traffic Growth Forecasting: Economic changes make long-term predictions challenging

- Vehicle Technology Evolution: Electric vehicles and autonomous trucks may alter load patterns

- Route Changes: New roads or improvements can redirect traffic unpredictably

- Regulatory Changes: Modified weight limits affect future MSA

Solutions and Best Practices

- Conduct long-term traffic monitoring programs

- Use regional databases and historical trends

- Apply appropriate safety factors in design

- Implement weight enforcement programs

- Update designs based on actual performance data

Impact of Overloading on MSA and Pavement Life

Vehicle overloading represents one of the most significant threats to pavement longevity:

The Overloading Problem

When vehicles exceed legal weight limits, the consequences for pavement structures are severe:

- A 10% overload causes approximately 46% more damage (1.1⁴ = 1.46)

- A 20% overload causes approximately 107% more damage (1.2⁴ = 2.07)

- A 30% overload causes approximately 186% more damage (1.3⁴ = 2.86)

Economic Implications

Studies have shown that widespread overloading can:

- Reduce pavement life by 30-50%

- Increase maintenance costs by hundreds of millions annually

- Require premature reconstruction decades ahead of schedule

- Create safety hazards through accelerated deterioration

Weight Enforcement Strategies

Effective weight enforcement protects infrastructure investment:

- Fixed and mobile weigh stations

- Weigh-in-motion technology for screening

- Automated enforcement systems with cameras

- Penalties and fines for violations

- Education programs for freight operators

MSA and Pavement Management Systems

Highway agencies integrate Million Standard Axles into comprehensive pavement management systems:

Strategic Planning Applications

- Network-Level Analysis: Prioritize maintenance across entire road networks based on MSA exposure

- Budget Allocation: Direct resources to high-MSA corridors with greatest economic impact

- Performance Monitoring: Track actual deterioration against MSA predictions

- Lifecycle Costing: Evaluate long-term costs of different pavement strategies

Project-Level Decisions

- Rehabilitation Timing: Schedule interventions before critical MSA thresholds

- Treatment Selection: Match rehabilitation methods to remaining MSA capacity

- Design Verification: Validate designs against actual MSA consumption rates

- Warranty Specifications: Base contractor warranties on MSA performance criteria

International Variations in MSA Standards

While the concept of equivalent axle loads is universal, different countries use varying standards:

| Region/Country | Standard Axle Load | Load Unit | Design Method |

| United States | 18,000 lbs (80 kN) | ESAL | AASHTO/MEPDG |

| United Kingdom | 80 kN | MSA | UK Design Manual |

| Australia | 80 kN | ESA | Austroads Guide |

| India | 80 kN | MSA | IRC Guidelines |

| Europe (General) | 100 kN | Variable | National standards |

| South Africa | 80 kN | E80 | South African method |

These variations reflect different vehicle fleets, regulatory environments, and historical research, but the underlying principles remain consistent.

Future Trends Affecting MSA Calculations

The transportation landscape is evolving, with several trends impacting Million Standard Axles:

Emerging Technologies

- Autonomous Vehicles: May optimize loads and routes for reduced pavement damage

- Electric Heavy Vehicles: Battery weight could increase axle loads

- Platooning: Concentrated loads in specific wheel paths

- Advanced Materials: Stronger pavements may alter MSA-thickness relationships

Policy and Regulatory Changes

- Higher Productivity Vehicles: Longer, heavier trucks with more axles

- Dynamic Load Management: Real-time weight monitoring and enforcement

- Performance-Based Standards: Focus on pavement damage rather than fixed limits

- Climate Adaptation: Design adjustments for changing weather patterns

Sustainability Considerations

- Recycled Materials: Impact on pavement performance and MSA capacity

- Carbon Footprint: Balancing durability with environmental impact

- Life-Cycle Assessment: Holistic evaluation beyond initial construction

- Adaptive Design: Pavements that evolve with changing traffic demands

Conclusion

Million Standard Axles represents far more than a technical calculation—it’s the foundation of rational, economical pavement design that protects billions of dollars in infrastructure investment. By converting the complex reality of mixed traffic into a manageable design parameter, MSA enables engineers to create road networks that reliably serve society’s transportation needs for decades.

Understanding MSA principles helps all stakeholders—from civil engineers designing new highways to policymakers establishing weight regulations—make informed decisions about pavement infrastructure. The exponential relationship between axle weight and pavement damage underscores the critical importance of weight enforcement and proper design.

As transportation technology evolves and climate patterns shift, the MSA concept continues adapting while maintaining its core purpose: ensuring that our roads withstand the cumulative impact of millions of vehicle passages. Whether you’re involved in designing, constructing, managing, or simply using road infrastructure, appreciating the role of Million Standard Axles provides valuable insight into the engineering that makes modern transportation possible.

Frequently Asked Questions

-

What is the standard axle load used in MSA calculations?

The standard axle load is typically 80 kN (18,000 pounds or 8.16 metric tons) carried by a single axle with dual wheels. This standard was established through extensive research and represents a common heavy vehicle axle configuration.

-

How does MSA differ from simple traffic counting?

MSA accounts for the damaging effect of different vehicle weights, not just the number of vehicles. A single heavily loaded truck can cause as much damage as thousands of passenger cars, which simple traffic counts don’t reflect.

-

Can pavements be designed for unlimited MSA?

No, all pavements have finite structural capacity. However, very thick pavements designed for high MSA (50+ million) can last 30-40 years or more under heavy traffic when properly maintained.

-

How accurate are MSA predictions?

MSA predictions involve uncertainties in traffic forecasting, vehicle weights, and growth rates. Good practice includes safety factors of 10-20% to account for these uncertainties and unexpected traffic increases.

-

Does pavement maintenance affect MSA capacity?

Yes, timely maintenance preserves structural integrity and can significantly extend the MSA capacity of existing pavements. Preventive maintenance is far more cost-effective than allowing pavements to deteriorate severely.